Building Envelope Air Sealing Key Strategies for Energy Efficiency

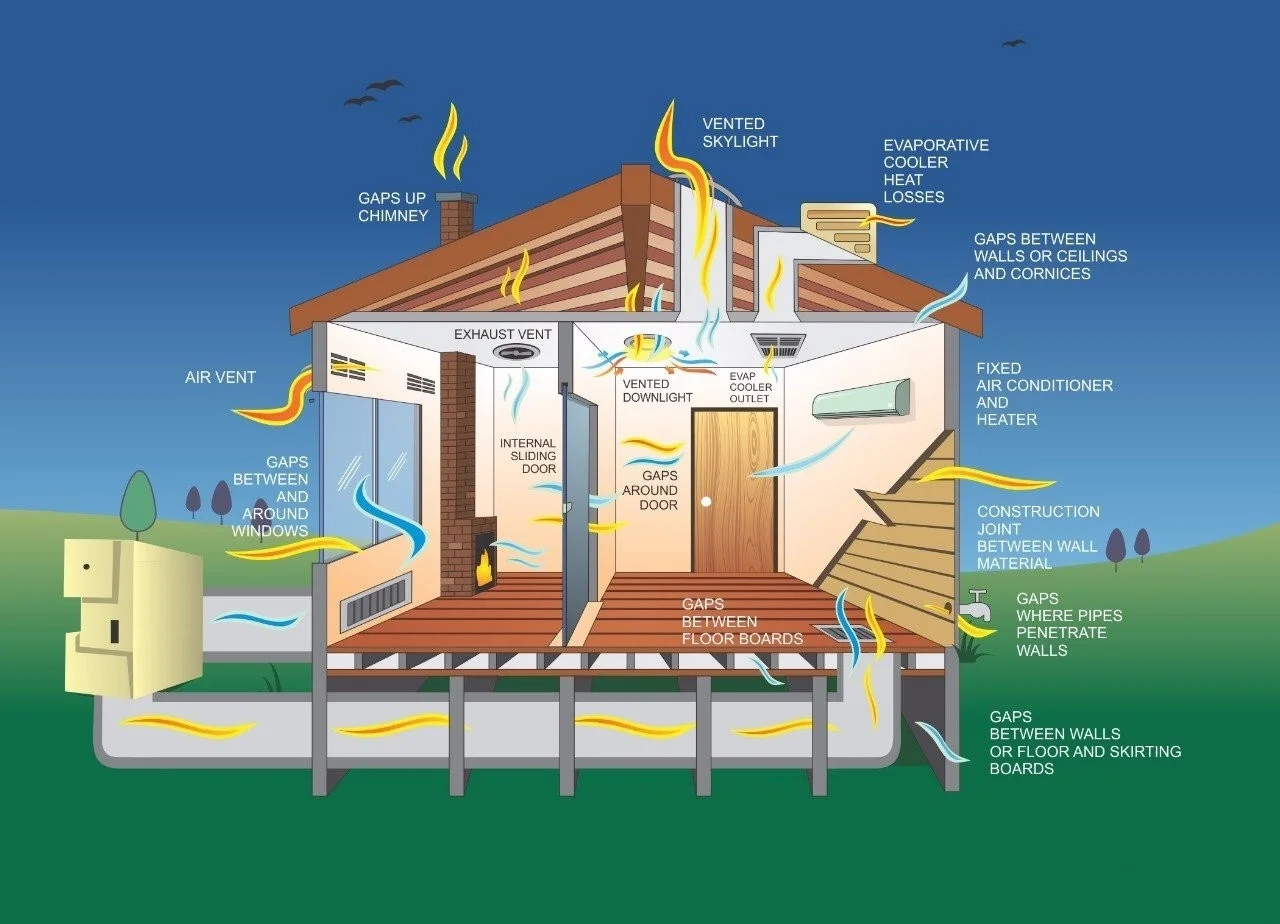

Air leakage is one of the quietest but biggest problems in a building. It lets treated air slip out, raises power costs, and puts extra strain on heating and cooling setups. The fix? Smart sealing with strong sealants. This method boosts heat control, handles dampness, and strengthens the outer layer of the building for the long run.

The Role of Air Sealing in Building Envelope Performance

The Relationship Between Air Leakage and Energy Efficiency

Air leaks make heating and cooling needs go up a lot. Outside air sneaks in or inside air gets out. Then, heating and cooling systems have to run harder to keep temps steady. This uses more energy and shortens their life. By cutting down on wild air flow, sealing keeps indoor spaces even. It lowers power bills and makes people feel more comfortable too.

How Sealants Enable Effective Air Barriers

Sealants play a key part in making solid air blocks around the building. They fill spaces between different stuff like glass and metal or concrete and wood. Silicone sealant is a paste-like substance that, upon contact with moisture in the air, cures into a tough, rubbery organic elastomer. Their stretchy quality lets them handle heat changes, building moves, and shifts with seasons without breaking or coming loose. Top-notch items like those from Kingdeli are built for lasting strength. They fight off bad weather and sun rays over years.

Impact of Air Sealing on Moisture Control and Durability

A tight outer layer isn’t only about saving energy. It’s also about making things last longer. Wetness from air leaks can build up inside walls. This leads to mold or broken materials. Well-placed sealants guard padding and frame parts from this sneaky danger. They boost the build’s strength and how long it holds up.

Key Locations for Air Sealing in the Building Envelope

Junctions Between Walls, Roofs, and Foundations

Spots where walls meet roofs and bases often mix various materials and shapes. These areas get gaps if not sealed with care. Using bendy sealants there keeps the air block going strong, even with shifting building weights.

Openings Around Windows, Doors, and Curtain Walls

Frames near windows and doors leak often. Weatherproof sealant is primarily used for sealing joints in curtain walls, ensuring their airtightness and watertightness. These seals need to deal with shifts from wind or heat changes. So, sealants that handle movement are key. Things like Kingdeli’s neutral silicone sealants work great here. They bond without harm and stay stretchy from –50 °C to +150 °C.

Penetrations for Mechanical, Electrical, and Plumbing Systems

Each tube, wire, or line that goes through the outer layer could be a weak spot. Putting sealants around them keeps things tight. Yet, it still allows changes or fixes later on.

Floor-to-Wall Connections and Structural Joints

At floor edges or hanging levels, side joints can widen from shakes or settling. Tough sealants with good sticking power help keep things solid in these busy spots.

Types of Sealants Used for High-Performance Air Sealing Systems

Silicone-Based Sealants for Long-Term Flexibility

Silicone sealants handle wide temp ranges and stand up to weather well. It has strong adhesive properties and high tensile strength, while also possessing weather resistance, shock resistance, moisture resistance, odor resistance, and the ability to withstand large temperature fluctuations. They stay bendy even in harsh weather, so they fit inside or outside jobs.

Polyurethane Sealants for Adhesion Versatility

Polyurethane sealants stick nicely to many surfaces like concrete, wood, or metal. They give solid strength too. Polyurethane (PU) has good cold resistance and wear resistance, but its heat resistance is inferior to that of silicone. People use them in moving joints where lots of flex is needed under pressure or shakes.

Hybrid Polymer Sealants for Environmental Resistance

Mixing perks from silicone and polyurethane, hybrid polymer sealants fight sun rays well and release few bad fumes. This makes them good for green building ways.

![]()

Integration of Sealants into Comprehensive Air Barrier Systems

Compatibility with Membranes, Tapes, and Sheathing Materials

Sealants have to stick firm to nearby items like weather guards or cover boards. Checking if they mix chemically is vital to stop peeling or breaks later.

Sequencing Sealant Application During Construction Phases

Putting on sealants too soon might get them hurt by later work. Doing it too late could mean hard access. Matching the timing with build steps is key for good coverage at main spots.

Climate-Adaptive Strategies Using Sealants in Different Regions

Hot Arid Climates: Managing Thermal Expansion with Flexible Sealants

In dry hot areas with big temp jumps, stretchy sealants handle growing and shrinking. They don’t lose grip or crack from sun exposure.

Humid Tropical Climates: Moisture-Tolerant Sealing Materials

Sealing stuff here must fight mold and work in wet air. HY-722 Sanitary Silicone Sealant.Well-suited for use in damp areas such as toilets and kitchens where fungal growth on sealants are prevalent.

Cold Climates: Maintaining Airtightness During Freeze-Thaw Cycles

Setting at low temps and keeping flex after cold is important for building in freezing spots. Sealants that stay bendy after ice help avoid splits at joins.

Evaluating Energy Savings from Effective Air Sealing Systems

Quantifying Leakage Reduction Through Measured Airtightness Improvements

Blower door tests check air swaps per hour (ACH). Lower ACH means less work for heating and cooling, plus better power use.

| Airtightness Level | ACH50 Rating | Implication |

| Passive House | ≤ 0.6 | Ultra-efficient |

| Standard Code | 3–5 | Average performance |

| Poor Sealing | > 7 | High energy loss |

Projecting Heating and Cooling Load Reductions from Improved Sealing

Tools for energy checks show how better sealing cuts yearly heating and cooling bills. This often pays off for fancy systems in time.

Enhancing Green Building Certifications Through Verified Airtightness

Plans like LEED give points for tight builds in energy sections. Right details with lasting sealants help get these awards when tests prove it.

Methods for Verifying Airtightness During Construction

Blower Door Testing as a Primary Diagnostic Tool

This test measures full building leaks under pressure changes. It points out bad areas that need more sealing before finish.

Infrared Thermography to Locate Thermal Bridging and Air Leaks

Heat pictures show odd temps from air getting out. They’re handy for checks to confirm how sealants work.

Smoke Testing for Visualizing Airflow Paths

Smoke shows exact paths of leaks around changes or holes. It’s useful during setup or fix-up checks.

Application Strategies Across Building Types

Incorporating Advanced Sealant Systems in New Construction Projects

Planning early lets you pick best joint designs and materials. On-site or factory-made options make sure sealing stays steady with build schedules.

Retrofitting Existing Buildings with Targeted Sealing Interventions

Old buildings usually have worn seals or open holes. Blower door checks let you fix just the bad spots without big messes. This brings back tightness fast.

Kingdeli is a specialized manufacturer of high-performance sealants and adhesives based in Foshan, China. With over two decades of R&D expertise, they offer tailored solutions for construction sealing needs—from weatherproofing curtain walls to insulating complex structural joints—ensuring durability across climates and building types.

Addressing Common Technical Questions About Air Sealing with Sealants

Q: How much can I save on energy bills by improving envelope sealing?

Savings vary by climate zone and starting condition but range from 5% to 30% annually.

Q: What airtightness level should I aim for?

Passive House: ≤ 0.6 ACH50; Standard Practice: 3–5 ACH50 depending on code requirements.

Q: Does tighter sealing hurt indoor air quality?

No—if paired with proper mechanical ventilation like HRVs or ERVs.

Q: Can I apply sealants myself?

Simple cracks may be DIY-friendly; complex joints or curtain wall transitions require professional handling.

Q: Is insulation enough without air sealing?

No—Insulation slows heat transfer; sealants prevent convective losses through leaks. Both work together for maximum efficiency.