Environmental Certifications and Standards for Sealant Products

Overview of Environmental Certifications in the Sealant Industry

Importance of Environmental Certifications for Sealant Products

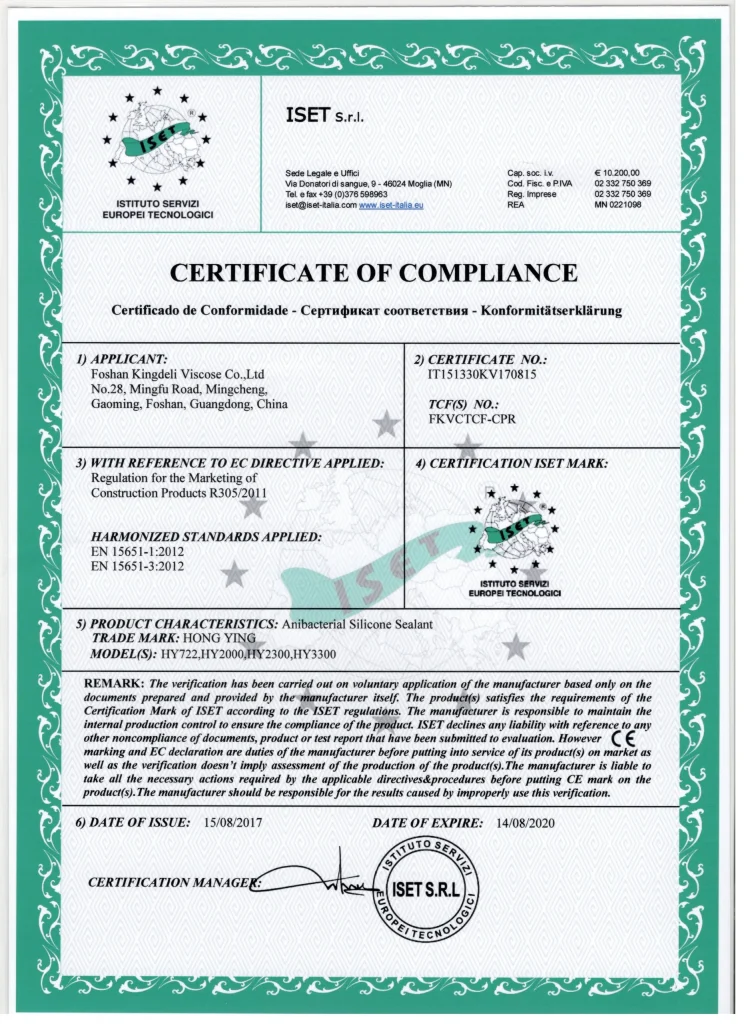

Environmental certifications hold significant value in the sealant sector. Foshan Kingdeli Viscose CO.,LTD possesses professional technical certifications,they confirm that products adhere to strict ecological and health benchmarks. With rising awareness of sustainability and indoor air quality, these certifications assure consumers and businesses alike. They guarantee that sealants are safe for both humans and the planet. Moreover, certifications motivate manufacturers to adopt sustainable production methods. This reduces their environmental impact.

For example, sealants with low VOC (Volatile Organic Compounds) emissions gain popularity. They improve indoor air quality. They also lessen harmful effects on health. Neutral Silicone Sealants, such as HY-2100 from Kingdeli, feature low VOC content. This makes them suitable for eco-conscious projects.

Key Benefits of Using Certified Sealants

Certified sealants provide numerous advantages:

- Health Safety: Certified products lower exposure to toxic substances. They protect users’ well-being.

- Environmental Protection: They reduce pollution during production and use.

- Compliance: Certified sealants align with green building codes like LEED (Leadership in Energy and Environmental Design).

- Market Preference: Eco-certified products often stand out. Consumers increasingly value sustainability.

Common Environmental Standards for Sealant Products

Understanding VOC (Volatile Organic Compounds) Regulations

VOC rules are vital for evaluating sealant compliance. VOCs are organic chemicals. They evaporate easily at room temperature. This contributes to air pollution and health concerns. Many nations enforce tight limits on VOC levels in construction materials.

For instance, HY-2300 Outdoor Neutral Silicone Sealant by Kingdeli has low VOC emissions. It ensures safety for the environment and users. Such products foster healthier spaces. They also support global efforts to address climate change.

LEED Certification and Its Relevance to Sealants

LEED certification is a widely accepted benchmark for sustainable construction. It assesses buildings based on energy savings, water efficiency, material choices, and indoor air quality. Sealants play a key role in earning LEED credits. They improve energy efficiency with airtight seals. They also enhance air quality by reducing VOC emissions.

GreenGuard Certification for Indoor Air Quality

GreenGuard certification emphasizes indoor air quality. It ensures products release minimal pollutants during use. This is crucial for sealants applied in homes or offices. Prolonged exposure in these spaces could pose risks.

Products like HY-722 Sanitary Silicone Sealant offer anti-fungus properties. They maintain low VOC levels. This makes them ideal for moist areas like kitchens and bathrooms.

Evaluating High Temp Silicone Sealants for Environmental Compliance

Characteristics of High Temp Silicone Sealants

High temp silicone sealants are engineered to endure extreme temperatures. They retain flexibility and adhesion. These sealants are used in industrial settings, automotive parts, and appliances like ovens.

For example, HY-939A Neutral Heat Resistant Silicone Sealant performs well from -60°C to 315°C. It suits engine gaskets, fuel pump covers, and heavy machinery. Its resistance to oil, sewage, antifreeze, and harsh substances enhances its versatility.

Environmental Standards Specific to High Temp Silicone Sealants

High temp silicone sealants must meet unique environmental criteria. This is due to their use in sensitive areas like food equipment or car interiors. These standards include:

- Low Emissions: They ensure minimal release of harmful substances during curing.

- Durability: They reduce waste with long-lasting performance under tough conditions.

- Non-toxicity: They remain safe during high heat or chemical exposure.

HY-949 Acetic Heat Resistant Silicone Sealant is designed for heavy-duty tasks. It complies with environmental safety norms. Its formulation prevents corrosion and pollution during application.

Clear Silicone Sealants and Sustainability Considerations

Features of Clear Silicone Sealants in Eco-Friendly Applications

Clear silicone sealants are valued for their eco-friendly qualities. They are a top choice in sustainable construction and manufacturing. These sealants have low VOC emissions. This improves indoor air quality. Products like HY-726 Premium Clear Neutral Silicone Sealant meet RoHS standards. They lack strong odors and corrosive elements. This ensures safety for users and the environment.

Their durability is another key trait. Clear silicone sealants perform across a wide temperature range. This reduces replacement needs. It minimizes waste and conserves resources. They also adhere well to substrates like glass, aluminum, and plastics. This versatility suits green projects.

Certifications Relevant to Clear Silicone Sealants

Environmental certifications validate the sustainability of clear silicone sealants. GreenGuard certification ensures minimal pollutant emissions. This makes them suitable for indoor use where air quality matters. LEED certification highlights their role in green building practices. They contribute points toward sustainability goals.

For instance, HY-722 Sanitary Silicone Sealant has low VOC levels. It offers excellent anti-fungus properties. This makes it perfect for damp spaces like kitchens and bathrooms. These certifications confirm compliance. They also boost appeal among eco-aware consumers.

Challenges in Achieving Environmental Certifications for Sealant Products

Regulatory Barriers and Compliance Costs

Obtaining environmental certifications involves navigating complex regulations. These vary by region. Manufacturers must conduct thorough testing. This ensures compliance with VOC limits or non-toxicity rules. The process is time-intensive and expensive. It poses challenges for smaller producers.

Compliance costs go beyond testing. They include changes to production methods. Sourcing eco-friendly materials adds to expenses. For example, creating HY-2300 Outdoor Neutral Silicone Sealant requires meeting strict VOC rules. It must also retain weatherproofing capabilities. Balancing these demands is tough. Manufacturers aim to certify products without sacrificing quality or affordability.

Balancing Performance and Sustainability

Developing certified sealants presents a key challenge. Manufacturers must balance performance with eco-friendliness. Sustainable formulas prioritize low emissions and safety. Yet, they must deliver strong adhesion, flexibility, and resistance to factors like UV rays or extreme temperatures.

High temp silicone sealants, like HY-939A Neutral Heat Resistant Silicone Sealant, exemplify this balance. They perform from -60°C to 315°C. They also meet environmental safety standards. Achieving this requires innovation in material science and formulation.

The Role of Manufacturers in Promoting Environmentally Certified Sealants

Sustainable Manufacturing Practices in the Sealant Industry

Manufacturers are central to advancing sustainability in the sealant sector. They adopt eco-friendly production methods. These include using renewable energy and minimizing waste. Recycling materials is another key practice. Closed-loop systems reclaim unused raw materials. This reduces environmental impact.

Foshan Kingdeli Viscose CO., LTD. demonstrates this commitment,and has the authority of the technical certification. Its 66,000-square-meter facility in Foshan, China, uses advanced production lines. These meet strict environmental standards. Such efforts enhance sustainability credentials. They also set benchmarks for the industry.

Innovations Driving Eco-Friendly Sealant Production

Innovation drives the creation of certified sealants. Advances in polymer technology enable low-VOC formulations. These maintain high performance. Modified silicone polymers allow quick curing at room temperature. They avoid releasing harmful substances.

Research into bio-based alternatives shows promise. Plant-based materials can replace petroleum-derived components. This lowers the carbon footprint. Smart technologies, like AI-driven quality control, improve efficiency. They minimize waste during production.

Frequently Asked Questions

What makes clear silicone sealants eco-friendly?

Clear silicone sealants are eco-friendly due to low VOC emissions. They are durable. They work with various substrates without releasing harmful chemicals during curing.

Are high temp silicone sealants safe for sensitive applications?

Yes, if they meet non-toxicity standards. Products like HY-949 Acetic Heat Resistant Silicone Sealant suit heavy-duty tasks. They adhere to environmental safety norms.

What certifications should I look for when choosing an environmentally friendly sealant?

Seek GreenGuard or LEED certifications. They ensure low pollutant emissions. They confirm compliance with sustainable building practices.

How do manufacturers contribute to sustainable sealant production?

Manufacturers use renewable energy. They recycle materials. They invest in research for low-emission formulas.

Where can I learn more about environmentally certified sealant products?

Foshan Kingdeli Viscose CO., LTD. offers solutions compliant with global standards. Its 30 years of expertise drive adhesive innovation.

Readers seeking sustainable solutions are invited to connect with us. Discover how Kingdeli’s innovation delivers environmentally certified excellence!