Glass Curtain Wall and Facade Glazing Systems Professional Sealing Guide

Glass curtain wall and façade systems depend a lot on the right choice and use of sealants. These materials do more than keep water out—they play a key part in structural strength, weather protection, and lasting performance. Mistakes in picking or putting on sealants can lead to expensive problems. This happens especially with building shifts or tough weather conditions.

Curtain Wall System Types and Their Sealing Implications

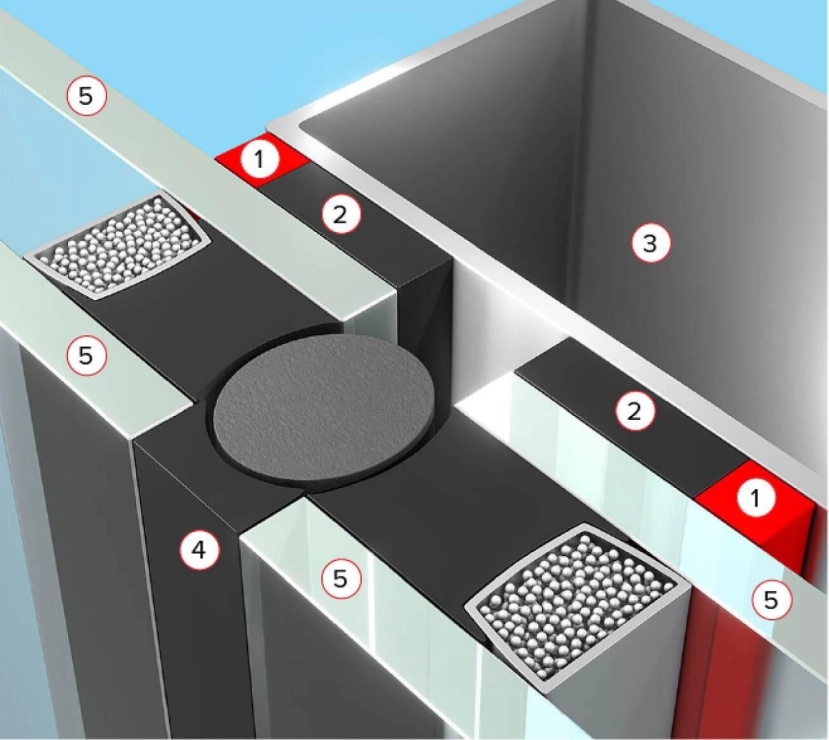

Stick-Built, Unitized, and Semi-Unitized Systems

Stick-built curtain walls get put together one piece at a time on site. So, they need more sealant applied in the field. This setup can cause more differences in work quality and contact with dirt from the air. On the other hand, unitized systems come pre-made in factories under good control. There, sealing turns out more steady and even. Semi-unitized systems mix both ways.

Factory sealing usually gives better handle on joint shapes and drying setups. But, fixes or connections done on site still call for exact methods and matching stuff.

Pressure-Equalized and Rain Screen Designs

Pressure-equalized systems use sections to deal with water entry. They do this by balancing air pressure in the wall space. This way cuts down on needing sealants as the main shield. Yet, it still needs careful work around joints.

Rain screen designs work to let water drain through the setup. At the same time, they stop it from getting inside. In both kinds, picking sealants has to match the design idea. They need to offer bendiness, resistance to sun rays, and strong sticking to different materials.

Structural and Non-Structural Glazing Interfaces

In structural glazing, sealants pass loads between glass and frames. So, their work is really important. By contrast, non-structural glazing mainly deals with keeping out weather. This allows for more options in sealants.

Sealants like silicone often get chosen. They have strong sticking power and good resistance to weather, including sun exposure and temperature changes.

Sealant Functions in Curtain Wall Assemblies

Structural Sealants for Load Transfer

For structural silicone to work safely, things like bite size (width of sticky contact), joint thickness, and edge space must get figured out just right. These sealants have to handle wind force, weight from above, and heat growth without breaking down over many years.

Kingdeli offers structural silicone solutions like HY-4300 that exhibit superior adhesion and excellent compatibility for most building materials, making them ideal for high-demand curtain wall applications.

![]()

Weatherproofing Sealants for Air and Water Resistance

Weatherproofing sealants need high stretch and firm sticking to surfaces like aluminum, glass, and coated metals. They also have to deal with big joint shifts without splitting or coming loose.

A product like Kingdeli’s HY-3300 fits this category well, offering durable flexibility and excellent UV resistance, vital for long-term performance.

Movement Accommodation in Joint Design

Curtain walls face shifts from wind forces, ground shakes, and heat changes. Sealants must have enough stretch room and bounce-back skill to manage these moves without ripping or staying bent out of shape.

Structural Silicone Specification and Application Criteria

Industry Standards for Structural Silicone Performance

ASTM C1184 and ETAG 002 outline stringent mechanical benchmarks for structural silicone, including:

| Property | Requirement |

| Tensile Strength | ≥ 0.14 MPa |

| Elongation at Break | ≥ 100% |

| Modulus at 10% Strain | Low or High as per spec |

| Adhesion/Cohesion | No failure allowed |

These standards ensure that silicone maintains its integrity under expected service conditions.

Joint Geometry Design for Structural Integrity

The recommended bite-to-thickness ratio generally falls between 2:1 and 3:1 depending on load requirements. Even small deviations in joint width during installation can compromise performance.

Load Calculations and Safety Margins in Design Phase

Designers must account for dead load (gravity), wind pressure, and dynamic impacts. International codes typically require safety factors of at least 5x for structural silicone applications.

Weatherproofing Sealant Selection Strategies

Functional Requirements for Façade Weatherseals

Essential characteristics include:

- UV resistance

- Water repellence

- Compatibility with glass, metal, gaskets

- High movement capability (often rated at 25–50%)

Silicone weatherproof sealants are preferred due to their long-term elasticity under extreme temperatures and UV exposure.

Silicone-Based Weatherseals: Performance Advantages

Silicone stays the top choice thanks to its high bond strength, weather resistance, and ability to keep up performance from −50 °C to +200 °C. These traits make it good for both outside joint sealing and hidden areas.

MS Polymer Alternatives in Façade Applications

MS polymers bring perks like being easy to paint and having low VOCs. Still, their bounce-back speed and sun resistance usually don’t match up to top silicones. This shows up especially in joints with lots of movement on building fronts.

Environmental Considerations for Sealant Selection

Desert Climate Challenges for Glass Facades

Strong sun exposure makes weak sealants age fast. Dust getting in during putting on also risks the sticking. Silicone’s Si–O backbone gives better sun stability. That’s because its bond energy beats out ultraviolet rays.

Tropical Climate Impacts on Sealing Systems

Tropical spots bring issues like:

- High wetness slowing dry times

- Mold growing on joints

- Sticking weakening over time

Sanitary-grade silicones like Kingdeli’s HY-722 can fight mold buildup while keeping their strength.

High Altitude and Cold Climate Adaptations

Sealants in cold areas have to make it through freeze-thaw rounds without cracking or peeling off. Up high, pressure differences can pull water into bad seals. Bendy silicones with low stiffness work best there.

Installation Techniques and Quality Control Measures

Surface Preparation Protocols Before Sealing Application

Surfaces must be clean, dry, and free of oils or dust. Primers may be necessary on porous or contaminated substrates to ensure proper adhesion.

Best Practices for Field Application of Sealants

Tooling the joint right after putting on ensures full contact without empty spots. Air temperature and wetness affect how fast it dries—so always follow what the maker says.

Testing Methods for Installed Sealing Systems

ASTM C794 adhesion tests validate bonding strength post-installation. ASTM E1105 water infiltration testing verifies air/water tightness of completed curtain wall sections.

Inspection Schedules and Maintenance Planning

Recommended Inspection Intervals Based on System Type

Curtain wall joints should be inspected every 3–5 years:

- Look for cracking, discoloration, or separation

- Document changes to support maintenance planning

Common Failure Patterns in Curtain Wall Sealing

Typical issues include:

- Poor surface prep leading to adhesion failure

- Joint dimension mismatches causing stress cracks

- UV degradation in exposed non-silicone joints

One small oversight during sealing can compromise years of otherwise solid performance.

As a specialized sealant manufacturer with over two decades of experience, Kingdeli supports glass wall sealing projects worldwide with products designed for structural strength, weatherproofing reliability, and environmental adaptability.

FAQs

Q1: Can one sealant type handle both structural bonding and weatherproofing?

A1: Not ideally. Structural sealants must bear loads; weatherproofing ones handle movement. Hybrid systems often use both types.

Q2: What’s the lifespan of a properly sealed curtain wall joint?

A2: With high-quality silicone like those from Kingdeli, lifespans often exceed 20 years under normal conditions.

Q3: How can I tell if a sealant is MS polymer or silicone?

A3: A simple heat test at 150°C can reveal differences—silicones resist bubbling or discoloration while MS polymers typically degrade.

Q4: Is priming always necessary before applying sealant?

A4: No, but it is essential on porous or difficult substrates to ensure bond performance.

Q5: What causes early sealant failure?

A5: Most commonly: incorrect joint design, poor surface cleaning, or using incompatible materials.