How RTV Gasket Maker Solves Common Engine Leak Problems

Introduction

Engine leaks show up in different ways. You may see oil drops on the ground, coolant dripping near the radiator, or smell exhaust fumes from small cracks. These issues look minor at first. But left alone, they grow into bigger, expensive damage. Normal gaskets often wear out because of heat, vibration, or age. When that happens, the seal breaks and fluids escape.

RTV gasket maker is now a common fix. RTV means “room temperature vulcanizing.” This silicone based sealant cures at room temperature and turns into a rubber like layer. Instead of using only pre cut gaskets, you can apply RTV directly on parts. It fills gaps and makes a seal that fits the shape perfectly.

Kingdeli makes RTV gasket makers designed for cars, trucks, and machines. The company has long experience in adhesives and sealants. Its products are built for real use, giving you lasting results in engines and equipment.

Why Engine Leaks Happen

Heat and Pressure in the Engine

Engines get very hot and run under pressure. Over time, the gaskets lose flexibility. They no longer press tight, and leaks start. RTV gasket maker, being silicone based, handles these heat cycles well. It stays stable and keeps sealing even after many runs.

Wear and Tear on Traditional Gaskets

Rubber and cork gaskets harden and shrink after years of use. They may crack under stress. RTV gasket makers stay flexible. They move with the parts and absorb shakes without breaking.

Chemical Exposure from Fluids

Engines carry oil, coolant, and other strong liquids. These fluids eat away at weak gasket materials. RTV sealants resist chemicals, so they keep sealing power even when soaked in engine fluids.

How RTV Gasket Maker Works

The Chemistry of RTV

RTV sealants are made from silicone. Silicone is known for being flexible, strong, and water resistant. When RTV touches air, it cures into a tough but bendable rubber. This cured layer grips metal, glass, and plastic, making it useful in engine zones where different materials meet.

Acetic Cure vs Neutral Cure RTV

There are two main kinds. Acetic cure RTV gives off a vinegar like smell when drying. It sticks very well to glass and metal but can affect sensitive surfaces. Neutral cure RTV is softer on materials and works well for sensors or coated parts.

Kingdeli provides both. HY-949 Acetic RTV Gasket Maker is for strong bonding on standard engine parts. HY-939 Neutral RTV Gasket Maker is better for delicate areas with sensors or electronics.

Electrical Safety and RTV

Silicone sealant is an insulator. That means it does not carry electricity once cured. It is safe to use around wiring, connectors, or sensors. The only warning is not to touch uncured RTV with live electrical parts.

Applications in Automotive Repairs

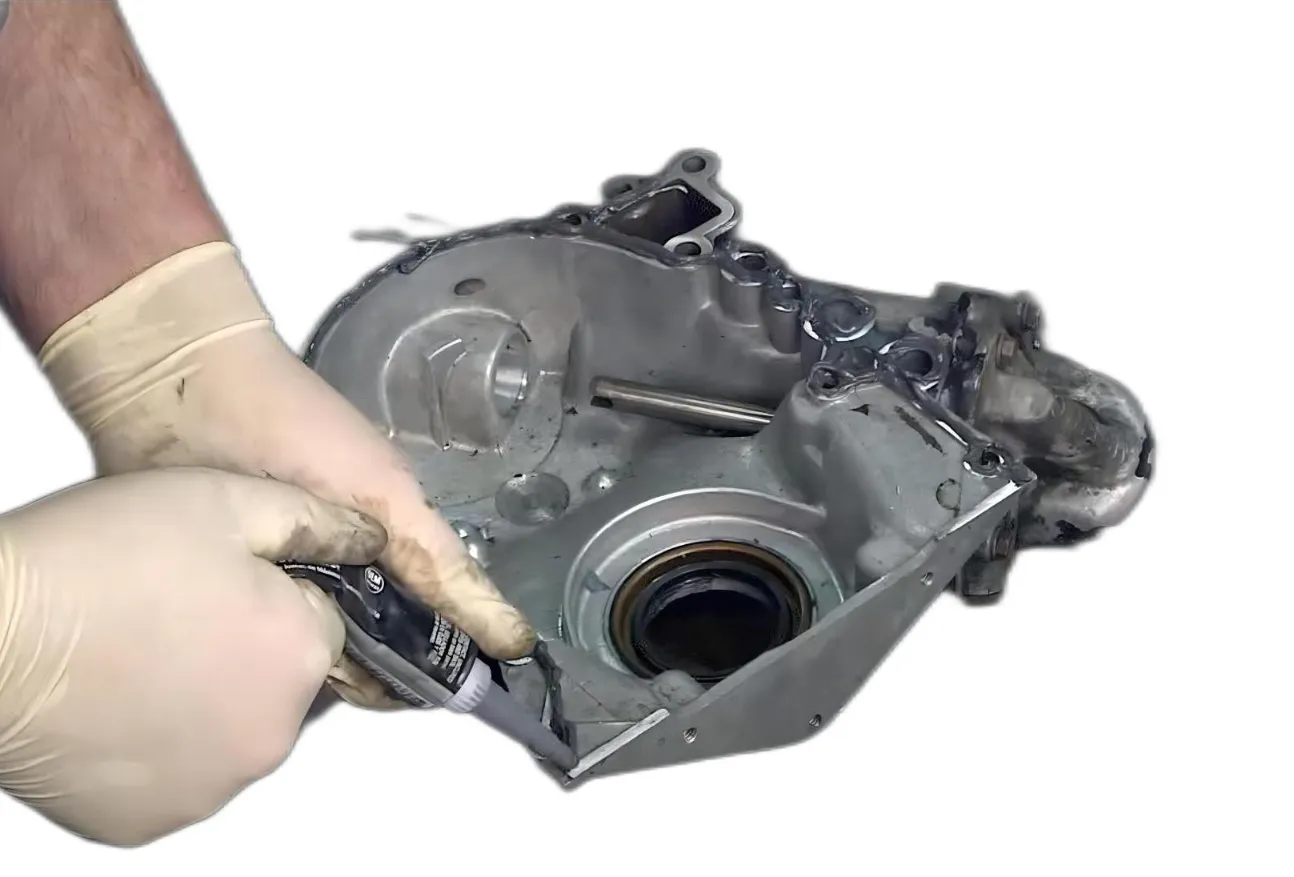

Oil Pan and Valve Cover Sealing

Oil pans and valve covers often leak first. They face hot oil and constant vibration. RTV gasket maker makes a strong line of seal around the edges, stopping oil from slipping out. Unlike pre-cut gaskets, RTV fills tiny flaws in the surface. This ensures no weak points.

Water Pump and Thermostat Housing

Coolant leaks are another headache. RTV resists coolant chemicals and stays elastic even when the engine changes from cold to hot. This keeps the cooling system sealed and steady.

Exhaust System and High Heat Areas

Some RTV products are built for extreme heat. They work on exhaust manifolds, turbo joints, and catalytic converter seals. Heat that destroys cork or paper gaskets does not harm silicone based RTV.

Sensor Safe Areas

Engines today rely on sensors. For these parts, neutral cure RTV such as HY-939 is safer. It avoids corrosion and protects sensitive parts. This is helpful for throttle bodies, intakes, and areas close to sensors.

Industrial and Equipment Uses

Heavy Duty Machinery

Engines in farm tractors or building machines run in dust, grease, and heavy loads. RTV helps cut downtime. You can seal leaks quickly without waiting for replacement parts.

Pumps and Compressors

Industrial pumps and air compressors shake a lot during use. RTV seals flanges and housings, standing up to vibration and oil exposure. This extends service life and lowers the chance of sudden breakdowns.

Marine Engines and Outdoor Equipment

Silicone sealants are known for resisting water and salt. RTV works well in boat engines and outdoor power units. It keeps moisture out and slows rust, even in tough marine settings.

Benefits of Using RTV Gasket Maker

Flexibility and Longevity

RTV stays elastic long after cork or paper gaskets fail. It can handle heating, cooling, and vibration without cracking. This gives you peace of mind and fewer repeat repairs.

Easy Application

RTV comes in a tube and applies directly. You don’t need to cut shapes. Once applied, it begins curing at room temperature. This makes repairs faster and less stressful.

Cost and Time Savings

RTV saves money by replacing rare or expensive gaskets. For older engines, where spare parts are hard to find, RTV becomes very useful. It also saves time in workshops since you don’t need to wait for deliveries.

About Kingdeli

Kingdeli has produced sealants and adhesives for over twenty years. The company offers eco-friendly products that also deliver strong performance. Its RTV line covers both acetic and neutral cure types, giving you options for different tasks.

If you want product help or technical advice, you can contact them directly.

FAQ

Q1: What parts can RTV gasket maker seal?

A: It works on oil pans, valve covers, thermostat housings, pumps, exhaust joints, and even industrial machines.

Q2: How long does RTV need to cure?

A: A skin forms in 20 minutes. Full cure takes about 24 hours. Thicker beads or low humidity may slow it down.

Q3: Is RTV safe for sensors?

A: Yes. Neutral cure RTV is safe for sensor zones. It avoids damage and is recommended for modern engine parts.

Q4: How does RTV compare to normal gaskets?

A: RTV seals better because it fills tiny gaps. Traditional gaskets may shrink or break, but RTV stays flexible under stress.

Q5: Why should you pick Kingdeli RTV products?

A: Kingdeli makes both HY-949 and HY-939. They combine durability with eco-friendly design and cover both heavy duty and sensitive tasks.