How to Choose Exterior Caulk for Different Surfaces: Wood, Concrete, Metal, and More

Choosing the Right Exterior Caulk for Wood Surfaces

Benefits of Using Poly Wood Sealer on Exterior Wood

When you’re sealing outdoor wood, like siding, trim, or railings, you need something that bends and holds up in bad weather. Polyurethane sealants are a great pick. They stick well and stay stretchy. HY-922 Multiple Purpose Polyurethane Sealant is a one-part sealant that hardens with moisture. It makes a tough, flexible joint and grabs onto most materials tightly. This is perfect for wood outside because wood grows and shrinks when it’s hot or cold.

Also, HY-922 fights off harsh weather, like rain or sun, and doesn’t sag over time. It lasts for years, even in rough conditions. Best of all, it’s safe, with no toxic stuff or solvents, so it’s kind to nature.

Comparing Acrylic Sealant and Poly Wood Sealer for Durability

Acrylic sealants are cheaper and simple to put on. But they don’t last as long as poly wood sealer. HY-972 High Elastic Acrylic Silicone Sealant lets you paint over it and keeps water out once it’s dry. It’s good for small gaps where things don’t move much. But it’s not the best for places hit hard by rain or wind.

Polyurethane sealants are tougher. They stretch more and handle rough weather better. For wood that faces sun, rain, or cold, poly wood sealer stays strong and lasts way longer than acrylic sealant.

Application Tips for Sealing Wooden Trim, Siding, and Joints

Before you start sealing wood:

Clean the surface really well.

Scrape away old caulk or bits of paint.

Check that everything is dry.

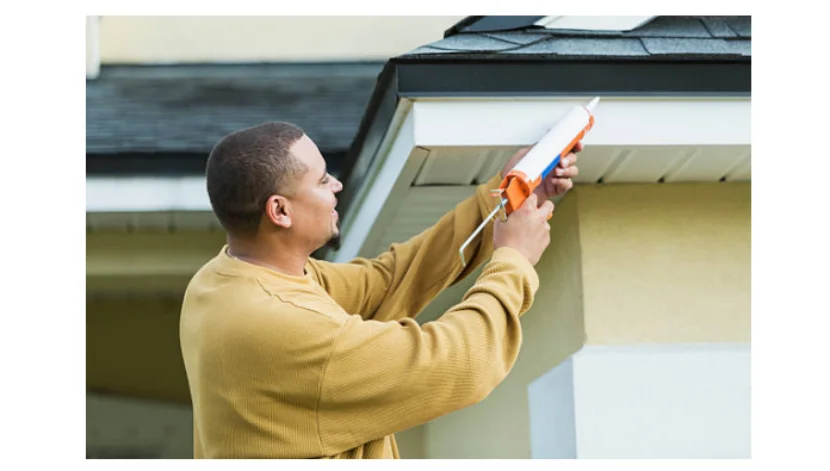

Grab a caulking gun and squeeze a smooth line of sealant into joints or cracks. Smooth it out with a caulking tool or a finger dipped in soapy water.

Best Caulking Solutions for Concrete Exteriors

Why Urethane Concrete Sealer Is Ideal for Outdoor Concrete

Concrete stuff, like driveways, foundations, or walls, needs sealants that can stretch and keep water out. HY-923 Low Modulus Polyurethane Sealant for Construction is a one-part sealant made for concrete joints that move a bit.

It stops water from getting in and sticks tightly to cement surfaces. Plus, it’s tough against wear, so it holds up even with cars driving over it or bad weather hitting it.

Performance Comparison: Acrylic Sealant vs. Urethane Concrete Sealer

Acrylic sealants, like HY-973, are okay for indoor concrete gaps. But outside, they don’t stretch enough for tough conditions. Urethane concrete sealer, like HY-923, is much stronger. It’s great for things like tunnel joints or sewage pipes, where water or frost could be a problem. Acrylic sealant just can’t keep up in those spots.

Effective Caulking Options for Metal Surfaces

Advantages of 100 percent Silicone Sealant on Metal Structures

Metal things, like gutters, flashing, or aluminum siding, need sealants that don’t fade in sunlight or rust the metal. HY-726 Premium Clear Neutral Silicone Sealant is built for sealing copper, gold, and all sorts of metal-coated mirrors. It blocks water and stays strong over time.

Its neutral cure means it won’t eat away at metals like aluminum or steel, which is super important.

Acrylic Sealant vs. Silicone: Which Performs Better on Metal?

Acrylic sealants don’t stick well to smooth surfaces like metal unless you use a special primer first. But 100 percent silicone sealant, like HY-726, works great in crazy temperatures, from -60℃ to 200℃. That’s perfect for outdoor spots where it gets hot or cold.

If you need a clear look, like around windows, HY-726’s see-through finish is way better than cloudy acrylic sealant.

Ensuring Long-Term Adhesion and Weather Resistance on Metal

Getting it right starts with prep:

Scrape off rust or old oxidation.

Wipe the surface with an alcohol-based cleaner.

Add a primer if the metal’s painted or the instructions say so.

Pick a top-notch 100 percent silicone sealant like HY-726. It sticks tight and keeps fancy coatings or finishes safe for a long time.

Multi-Surface Use: Selecting Versatile Caulks for Mixed Materials

When to Use Acrylic Sealant Across Different Exterior Materials

Acrylic sealants are handy for lots of materials in spots that don’t move much, like window frames touching drywall or brick. High Elastic Acrylic Silicone Sealant sticks to metal, PVC, wood, concrete, and gypsum boards. It’s awesome for places where indoors meets outdoors, like around doors or trim.

You can paint it once it’s dry, which is great if you want it to match the wall or frame color.

Combining 100 Silicone percent Sealant and Acrylic Sealant for Hybrid Applications

For projects with different materials, like glass and concrete, using both sealants can be smart:

Go with 100 silicone sealant where you need it to stretch and keep water out.

Use acrylic sealant where you want to paint it or stick to rough surfaces.

Put each sealant only where it works best. Don’t mix them unless the maker says it’s fine to do so.

Surface Preparation Techniques to Maximize Sealant Performance

No matter the material:

Clean everything super well.

Make sure it’s totally dry.

Don’t try caulking when it’s freezing cold.

For big joints (wider than 6mm), pop in a backer rod before sealing.

Look at the product datasheets from Foshan Kingdeli Viscose CO.,LTD. to see if you need a primer for your surface.

Key Factors to Consider When Selecting Exterior Caulk

Flexibility and Expansion Capabilities of Poly Wood Sealer and Urethane Concrete Sealer

Stuff outside moves when it gets hot or cold, so you need stretchy sealants to avoid cracks. HY-922 poly wood sealer bends without breaking. HY-923 urethane concrete sealer stays strong even when things shift a lot. These are awesome for joints that move with the seasons or heavy structures.

Compatibility with Paints and Coatings in Outdoor Environments

If looks matter, paintability is a big deal. Acrylic sealant takes paint like a champ once it’s dry. Most silicones don’t let paint stick unless you treat the surface first. Always test your paint (latex or oil-based) before you go all in to make sure it works.

FAQ Section

What’s the difference between acrylic sealant and silicone?

Acrylic sealant is water-based and paintable after it dries. It’s good for indoor or outdoor spots with little movement. Silicone sealant bends more and handles weather better, but paint doesn’t stick to it easily.

Can I use one type of caulk across wood, concrete, and metal?

Not the best idea. Each material has its own needs because of texture and movement. Mix acrylic sealant for paintable spots with silicones or polyurethanes for stretchy, weatherproof seals.

What’s the best exterior caulk that doesn’t crack over time?

For stuff that lasts outside, go with polyurethane sealants like HY-922. They stay bendy through temperature swings and heavy movement.

How do I ensure proper adhesion before applying exterior caulk?

Clean the surface super well. Get rid of dust, oil, or old caulk. Make sure it’s dry. Use a primer if the product instructions tell you to.

Check out our wide range of pro-grade adhesives at Foshan Kingdeli Viscose CO.,LTD. We can customize products to fit your project. After almost 30 years, Kingdeli is a top player with strong skills in the industry.