How to Select the Right Waterproof Sealant for Equipment Penetrations

Picking the right waterproof sealant for equipment penetrations is not just about filling a gap—it is about making sure of lasting results under shifting weather pressures, material matches, and shifting movements. Whether you seal rooftop HVAC units or underground drainage setups, choosing well can stop expensive water harm and building wear.

Key Factors in Choosing a Waterproof Sealant for Equipment Penetrations

Environmental Exposure and Moisture Conditions

First, check the setting. Is the penetration out in strong sun rays or cold-freeze shifts? Rooftop and outside wall spots need sealants with great weather and UV strength. For instance, silicone sealants have traits like weather strength, shake strength, damp strength, smell strength, and fit for big heat changes—so silicone-based sealants work well for changing settings. If the area has factory chemicals, make sure chemical strength is in the product’s details.

Lasting strength also changes by weather. Beach areas may need items with better salt-mist strength. And cold spots call for bend at very low heats.

Compatibility with Substrates and Adjacent Materials

Sealant stick must be steady across various bases—concrete, metal, PVC, EPDM roofing membranes. It shows great stick to many factory materials, including glass, ceramics, wood, painted surfaces, and many metals and plastics.

Also, skip chemical mismatches. A tough sealant might still bring problems if it reacts badly with padding, covers, or nearby waterproof layers. Always look at maker tips.

Movement and Vibration Tolerance

Equipment penetrations are seldom still. Shakes from machine parts or heat growth can pull or push joints. Weatherproof sealant is mainly used for sealing joints in curtain walls, making sure they stay air-tight and water-tight. It must also have some shift ability. Look for items with high stretch rates and low firmness to handle active joint shifts without breaks.

Types of Sealants Used in Penetration Waterproofing

Polyurethane-Based Sealants

Polyurethane sealants exhibit excellent adhesion to a variety of materials and can withstand typical joint movements, such as Kingdeli’s HY-922 polyurethane sealant.

Due to its relatively low UV resistance, it is best suited for applications in areas not exposed to sunlight, such as underground or within walls, and is suitable for joint sealing, simple bonding, and vibration damping.

Silicone-Based Sealants

Silicone sealant, upon contact with moisture in the air, cures into a tough, rubber-like organic elastomer. It features weather resistance, shock resistance, moisture resistance, odor resistance, and adaptability to wide temperature variations.

These traits make silicone great for rooftop and open setups. Kingdeli’s HY-3300 Weatherproof Neutral Silicone Sealant keeps up performance between -50 °C to +200 °C, just right for high-open zones.

Hybrid Polymer Sealants (MS Polymer, STPE)

Hybrid sealants combine flexibility and adhesive strength. HY-994 all purpose MS polymer sealant offers excellent UV resistance, weatherability, and temperature resistance. These sealants are paintable, low-VOC, and typically require no primer, making them ideal for interior and multi-material applications.

Expanding Foam Sealants (Polyurethane Foam)

Handy as fillers in ring spaces around pipes, these foams grow to block empty spots. But they miss surface toughness and must be covered with a proper waterproof top to make sure no water gets in.

Application Considerations Based on Penetration Location

Roof Equipment Penetrations

Rooftops call for UV-steady items that fit roofing layers like TPO or EPDM. Silicone sealants do well here. Mixing with flashing setups and maybe pre-shaped covers stops leaks from standing water.

Wall-Mounted Equipment Penetrations

Outside wall spots need bend to take in building settle while fighting wind-pushed rain. Fit with outer cover systems is key—especially when sealing around meters, electrical boxes, or vents.

Below Grade Equipment Penetrations

Water push from below is a big test underground. Mix bendy layers with sealants like polyurethane or hybrid choices. Use water-react grouts or water-loving sealants where steady damp is there.

Design Integration with Waterproofing Systems

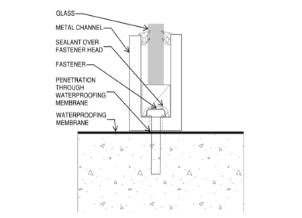

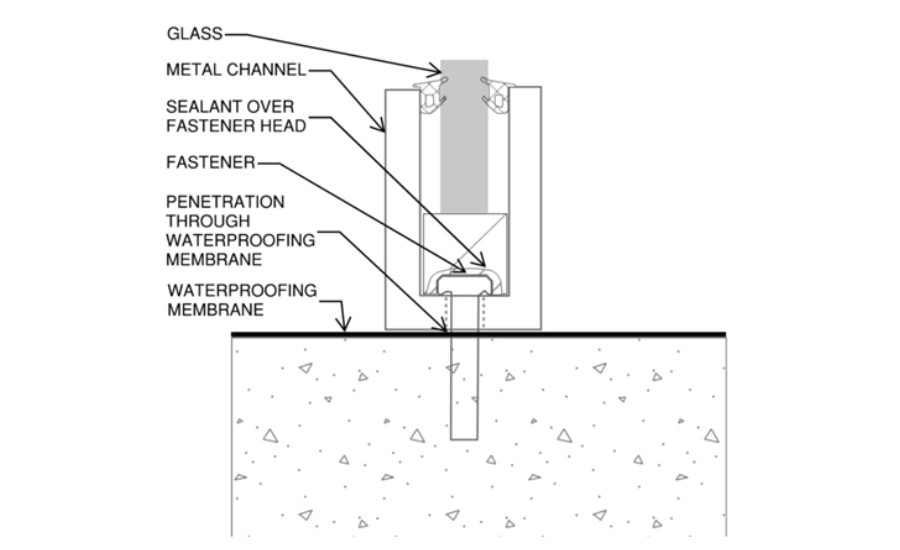

Coordination with Membrane Waterproofing Assemblies

Make sure steady flow at changes—especially where liquid-put layers meet penetration seals. Avoid blending mismatched items that may split over time.

Sleeve Design and Annular Space Management

Right-sized sleeves let backer rod place and best sealant depth-to-width rates. Gaps should be filled with no-shrink backfill before putting the outer sealant layer.

Performance Criteria for Long-Term Durability

Curing Mechanisms and Installation Conditions

Some sealants need air damp to set—moisture-cure kinds are touchy to wet levels. The curing mechanism of single-component products is related to environmental conditions; higher temperature and humidity lead to faster curing. Make sure site settings help full set before water hits.

Resistance to Aging, Cracking, and Adhesion Loss

Look for ASTM C920 compliance. Products like Kingdeli’s HY-2300 have been tested under standards such as JC/T882-2018 and maintain performance in -50 °C to +150 °C ranges.

Addressing Common Challenges in Equipment Penetration Sealing

Dealing with Irregular Openings or Complex Geometries

Use shootable sealants that shape easy to non-straight forms. Shaping the bead makes sure full cover and touch.

Sealing Around Existing Leaks or Retrofit Installations

Take out old or bad stuff fully before putting new sealant. Primers may be needed on old or dirty bases.

Managing Grouped or Bundled Penetrations

Use split covers or rings before putting the last sealant layer. Plan for easy reach so later fixes won’t hurt the waterproofing.

Maintenance Strategies for Long-Term Waterproofing Integrity

Inspection Schedules Based on Exposure Risk

Check rooftop spots two times a year because of UV and heat cycles. Wall-mounted units can be looked at during yearly outside checks.

Repair Techniques Without Full System Replacement

Cut out bad parts clean before resealing. Re-prime if maker details have shifted since first setup.

Product Selection Tips Aligned With Project Requirements

Evaluating Manufacturer Specifications Against Site Conditions

Look over data sheets close—cure time, firmness, stretch %, UV score count. Field checks on new bases help confirm fit.

Working With Qualified Suppliers and Applicators

Teaming with skilled suppliers like Kingdeli gives tech help during plan steps and reach to a broad product set. Based in Foshan, China since 1998, Kingdeli specializes in adhesives and sealants for construction waterproofing, bonding, and repair applications.

Regulatory Compliance and Specialized Applications

Fire-Rated Equipment Penetration Requirements

Use UL-listed firestop sealants when required by code. Coordinate firestopping details early to avoid conflicts with waterproofing layers.

Sealing Around Vibrating Mechanical Equipment

Pick rubbery items rated for active loads. Machine boost may be needed near spots of steady shakes.

Troubleshooting Persistent Water Intrusion Issues

Diagnosing Failures Related to Improper Application

Look at fails close—inner fail means inside break; stick fail points to surface ready problems. Training workers helps skip these slips.

Solutions When Flashings or Boots Deteriorate Over Time

Swap out weak parts quick. Think about better details using liquid-put flashing systems for longer stick life.

FAQs

Q: What is the best sealant type for rooftop HVAC penetrations?

Silicone-based sealants are ideal due to their superior UV resistance and flexibility across temperature extremes.

Q: Can expanding foam be used alone as waterproofing?

No. Expanding foam must be topped with a flexible outer sealant layer to ensure watertightness.

Q: How do I know if a sealant will stick to my substrate?

Check the product’s technical sheet and perform an adhesion test on-site if the substrate is unfamiliar.

Q: Are all silicone sealants the same?

No. Silicone products vary by modulus, curing system (acidic vs neutral), and intended use—read labels carefully.

Q: Why choose a supplier like Kingdeli?

Kingdeli provides tested, certified solutions tailored for industrial waterproofing needs along with technical guidance for your application.