The Science of “Flexible Sealing” in Polyurethane Sealant

Properties That Define Polyurethane Sealant Performance

Chemical Composition and Its Role in Flexibility

Polyurethane sealants are made from special polymers that have urethane connections. These connections give the material a nice mix of being strong and bendy. This mix lets the sealant stretch and move without breaking apart. For example, the one-component, moisture-curing HY-922 Multiple Purpose Polyurethane Sealant creates a joint that’s tough but can flex. It sticks really well to lots of different surfaces. These sealants stay bendy for a long time, even when they face rough weather or other hard conditions.

Elasticity and Elongation Characteristics

The stretchy nature of polyurethane sealants makes them perfect for joints that wiggle or shift. Products like HY-923 Low Modulus Polyurethane Sealant for Construction are built to handle big movements. They’re great for expansion joints or places that move a lot. This bendiness helps the sealant deal with changes from heat, building settling, or shaking. It stays glued on tight and doesn’t crack.

Adhesion Capabilities on Diverse Surfaces

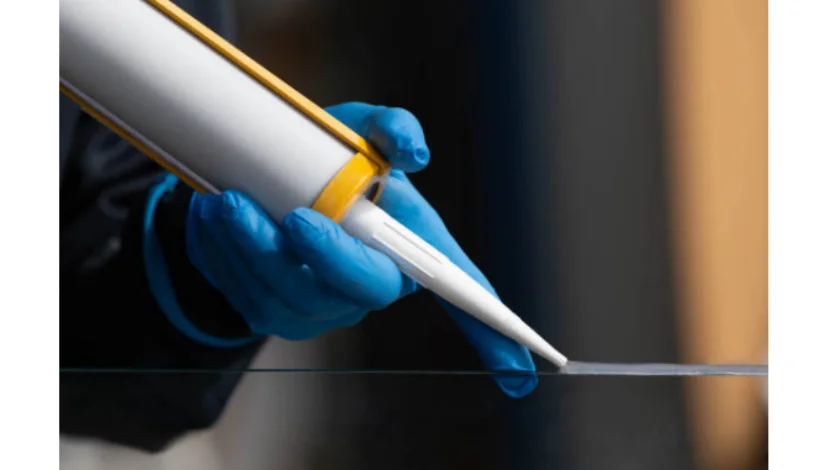

Polyurethane sealants grab onto all kinds of materials, like concrete, metal, glass, wood, and plastic. For instance, HY-924 Polyurethane Adhesive For Windshield sticks super well without needing a primer. This no-primer trick makes it easier to use while keeping a strong hold.

Mechanisms Behind Flexible Sealing Technology

Polymer Chain Behavior Under Stress

At the super tiny level, polyurethane sealants have long chains of molecules. These chains can twist and shift when they’re pushed or pulled. This lets the sealant stretch when it’s tugged and bounce back to its shape when the tugging stops. The bendy parts of the chains work like little springs. They soak up the stress instead of pushing back against it.

How Polyurethane Sealants Absorb Movement

When you put polyurethane sealants in gaps or joints between building pieces, they act like soft cushions. They take in stresses, like when things stretch from getting hot or shrink from getting cold. Products like HY-925 Polyurethane Sealant for Construction are awesome at sealing and sticking. They stay strong even under tough pressure or harsh conditions. This makes them a great choice for tricky places like bridges or drainage pipes.

Environmental Resistance and Long-Term Stability

One of the best things about polyurethane sealants is how tough they are against weather, UV rays, water, and chemicals. HY-922 is really good at handling weather and doesn’t creep or sag. It stays solid even when it’s outside all the time. It’s also safe, with no toxins, no solvents, low VOCs, and it’s kind to the planet. This makes it perfect for green building projects.

Applications of Polyurethane Sealant in Construction and Industry

Common Uses in Expansion Joints and Façade Sealing

Polyurethane sealants are used a lot in construction for places that move, like expansion joints in concrete slabs or façade sections. HY-923 is awesome for sealing tunnel joints or areas that settle. Its low modulus design lets it handle big shifts without breaking.

Advantages for Waterproofing and Vibration Damping

Besides sealing, polyurethane sealants keep water out. This is super important for places like sewage pipes or reservoirs that stay underwater. They also help quiet down vibrations, which is really handy in car manufacturing. For example, HY-924 is used a ton for bonding auto side and back window glass. It’s both bendy and strong, which is exactly what’s needed.

Performance in Temperature Fluctuations and Humidity

Big temperature swings can make building materials grow or shrink a lot. Polyurethane sealants stay tough through all kinds of temperatures because they’re naturally stretchy. HY-925 stays bendy in freezing cold or super hot weather. This makes it great for all sorts of climates.

How Kingdeli Enhances Flexible Sealing with Advanced Manufacturing

Overview of Kingdeli’s Production Capabilities

Since starting in 1998, Kingdeli has grown into a big-time maker of sealants, adhesives, and coatings in Foshan, China. Their factory covers 66,000 square meters and has over 150 workers. They can make 100,000 tons of product every year.

Quality Control Measures Ensuring Consistency

Kingdeli is super serious about checking quality at every step. From the raw stuff to the final product, their quality team looks at everything. This makes sure every batch is top-notch before it heads out the door.

Use of Automated Lines to Optimize Material Properties

Kingdeli uses fancy, fully automated production lines. These machines carefully control how materials are mixed and cured. This care makes sure things like stretchiness or curing speed are just right, keeping the quality steady.

Factors to Consider When Choosing a Polyurethane Sealant

Matching Sealant Flexibility to Application Needs

Not all polyurethane sealants are the same. Some are stiffer, with higher modulus, while others, like HY-923, are super bendy for joints that move. Figuring out how much your project’s joints will shift is key to picking the right one.

Durability Expectations Based on Project Type

For projects in rough conditions, like roofing tiles or underwater surfaces, choose sealants that can handle UV rays, water, or extreme temperatures. Kingdeli’s polyurethane products, like HY-922, are made for these tough jobs.

Kingdeli can tailor their products to fit your project’s special needs. Get in touch to see how they can help you out.

Frequently Asked Questions (FAQ)

Q: Why are polyurethane sealants so bendy?

A: Their chemical makeup has soft molecule bits. These bits stretch when pushed and go back to their shape when the push stops. This keeps them from cracking when things move.

Q: Are polyurethane sealants waterproof enough for underwater jobs?

A: Yup. Products like HY-922 are made for places like drains, reservoirs, or sewage pipes that are underwater a lot.

Q: Should I pick a stiff or bendy sealant?

A: Go for high modulus for still surfaces, like fixed panels. Choose low modulus, like HY-923, for joints that shift a lot.

Is surface preparation necessary before applying polyurethane?

Q: Do I need to clean surfaces before using these sealants?

A: Some products, like HY-924, don’t need primers. But it’s smart to clean off dust, oil, or water for the best stick.

To find out more about cool sealing options or get expert advice for your project, contact Foshan Kingdeli Viscose CO.,LTD today.