Two Part Epoxy Grout Explained: How It Outperforms Cement Grout

Key Differences Between Two Part Epoxy Grout and Cement Grout

Composition and Chemical Structure

The basic makeup of two part epoxy grout and cement grout differs a lot.

- Epoxy Tile Grout mixes resin and hardener. These parts react chemically when you apply them. They create a strong, solid material. It holds up well in tough spots.

- Cement grout uses Portland cement instead. You mix it with water. Sometimes you add sand or other fillers too. It hardens through hydration. That’s a slower process. It ends up more porous.

Their chemical differences matter. Epoxy grout makes a smooth, non-porous shield after it sets. Cement grout stays open to outside effects.

Installation Process and Handling Characteristics

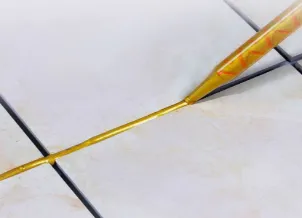

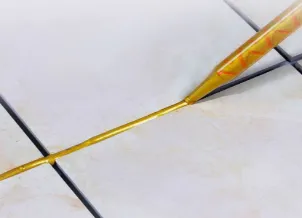

Putting them in takes different efforts. You must mix epoxy grout’s resin and hardener just right. Time counts a lot here. It has a short working time. So workers need to move fast. They also clean up right away before it gets hard.

Cement grout is simpler to handle. Just add water and spread it with a float. Yet drying can change with room temperature or wetness in the air. That might cause uneven setting sometimes.

Pros often pick epoxy for big or hard jobs. Cement grout suits home folks or DIY types better. It’s more easygoing.

Performance in High-Stress Environments

In tough places, two part epoxy grout does much better than cement.

- Epoxy Tile Grout fights off chemicals, spots, and water well. These traits help in busy kitchens, medical spots, and factory areas.

- Cement grout has holes in it by nature. Seals help a bit. But it can crack or shrink as time goes on. Water or heat changes make it worse.

When clean or strong build is key, go with epoxy.

Durability and Longevity in Real-World Applications

Resistance to Moisture and Staining

Epoxy’s closed-up build gives it a strong lead.

- Epoxy Tile Grout seals out water tight. It won’t soak up spills. Mold can’t grow there either.

- Cement grout soaks up water unless you seal it. Even sealed, it darkens or spots after many spills over years.

So epoxy works great in baths, kitchens, and pool spots.

Color Retention Over Time

Color plays a big part in looks. This holds true over wide tile areas.

- Two part epoxy grout keeps its shade steady. It handles sun light or lots of washing fine. Take epoxy grout grey. It stays the same even with regular scrubbing.

- Cement grout shifts color often. White powdery stuff or strong cleaners cause it.

Steady looks keep the design right for a long while.

Maintenance Requirements in Long-Term Use

Keeping them up varies between the two types.

- Epoxy Tile Grout asks for little care. The sealed top fights dirt. No need to seal again.

- Cement grout needs seals now and then. Clean it gently too. That stops color loss and wear.

Less work over years means lower costs and effort for epoxy folks.

Aesthetic Considerations in Tile Design Projects

Range of Available Colors and Finishes

How it looks often decides in fancy design work.

- Epoxy grouts offer many color choices. Think popular ones like epoxy grout grey. They match new tiles well.

- Cement grouts have fewer options. Drying can make colors spotty too.

Epoxy draws in designers who want exact looks.

Visual Consistency Across Large Installations

Big jobs show any flaws clear.

- Epoxy grout sets even because of its set chemical change. You get the same color in rooms or whole buildings.

- Cement grout can look uneven. Wrong water amounts or drying waits cause patches. Light makes it stand out more.

Tile pros often choose epoxy for jobs needing perfect evenness.

Application Scenarios for Each Grout Type

Residential vs Commercial Use Cases

The place tells which grout fits best.

- Two part epoxy grout shines in business spots like eateries, labs, and clinics. Clean and strong build matter there.

- Cement grout shows up more in home jobs. Upfront costs are lower.

Still, smart homeowners pick epoxy for wet spots like showers or door areas now.

Suitability for Wet Areas or High Traffic Zones

How they hold under use shows clear differences. Epoxy’s water-proof side makes it right for pools, hot tubs, changing rooms, and wet places.

Cement grouts break down easy without good seals. Even sealed, they last less with steps or pooled water. In spots with heavy action, epoxy comes out on top.

Technical Advantages of Two Part Epoxy Grout Formulations

Chemical Resistance and Structural Integrity

Factory settings ask a lot from stuff. Epoxy Tile Grout stands up to acids, bases, oils, and cleaners in work areas.

It keeps its hold strong through heat shifts and rough use. That fits busy making or handling spots. This strong build means longer use even in hard spots.

Elimination of Sealing Requirements Post Application

No more steps after it sets. That’s a real help. Epoxy Tile Grout builds its own top shield when cured. No extra seal needed.

This cuts work costs. It also skips repeat care over time. For bosses watching money over years, not just short times, it’s a key win.

Considerations When Choosing Between Grout Types

Cost Implications Over Time

Starting price vs full life cost. They don’t match.

- Epoxy runs higher at first per area. But its long life and less care save money later.

- Cement grout looks cheap to start. Yet seals, fixes, or swaps add up quick.

Pickers should look at full cost, not just the buy price.

Skill Level Required for Proper Installation

Not all workers handle every type well.

- Epoxy needs pros who know fast-set stuff and clean rules.

- Cement grouts forgive mistakes more in putting on. They fit DIY or newer workers.

Worker skills really affect if epoxy jobs go right.

Industry Trends Favoring Advanced Grout Technologies

Movement Toward Low-Maintenance Materials

The change shows in home fixes to big builds. Builders and planners call for epoxy grouts more for steady work.

Folks want stuff that cuts earth harm by less care. Users like clean tops without always watching or using cleaners. Epoxy does that well.

Integration with Modern Building Materials

New tile types need better sticks and fills. Epoxy mixes good with glass tiles, clay boards, and big clay pieces.

Porcelain tile jobs gain from epoxy’s stick power. Like ones from Kingdeli. Working together gives sure results with new trends.

Role of Manufacturers Like Kingdeli in Product Innovation

Focus on Multi-Surface Compatibility

Today’s builds need all-around fixes. Kingdeli makes stick aids that boost epoxy grouts on different bases. From tile on cement to stone on glass, new ideas make it work on many grounds.

Contribution to Sustainable Construction Practices

Green ways aren’t just popular. They’re rules in some places. Low air-harm mixes fit green build checks. This helps makers hit green goals while keeping strong standards.

Support for Industrial and Residential Applications

Makers must help big and small jobs well. Kingdeli’s line covers huge works and home fixes with solid fixes.

That ease makes getting supplies simple for workers on varied tasks.

FAQ

Q: What is two-part epoxy grout?

A grout made by mixing resin and hardener, which chemically reacts to form a strong, non-porous, waterproof, and stain-resistant material.

Q: What are the main differences between epoxy grout and cement grout?

Epoxy grout is non-porous, waterproof, stain- and chemical-resistant; cement grout is porous, absorbs water, requires sealing, and is prone to cracking or discoloration.

Q: What are the main advantages of epoxy grout?

Waterproof and mold-resistant, highly stain-resistant, chemical-resistant, long-lasting color, no sealing required, and low maintenance for longer lifespan.

Q: Which applications is epoxy grout best suited for?

Ideal for wet areas and high-traffic commercial spaces (restaurants, hospitals), outperforming cement grout.

Q: Is epoxy grout difficult to install and is it more expensive?

Requires professional installation, higher initial cost, but saves money long-term through reduced maintenance and replacements.